|

Quanzhou Xinda Machinery Co.,Ltd.

|

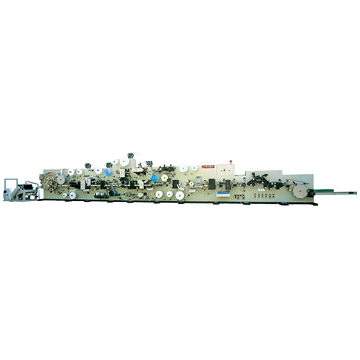

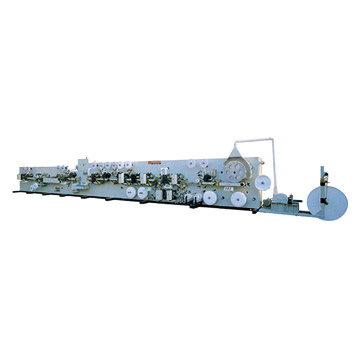

Dot-by-Dot High Speed Rewinding Perforated Paper Machine

| Place of Origin: | Fujian, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Features:

1) High automation, complete function and high efficiency programmable control

system

2) Automatically exchanges core, then wi

Features:

1) High automation, complete function and high efficiency programmable control

system

2) Automatically exchanges core, then winds, sprays glue and seals without stopping

3) Automatically raises and lowers speed when exchanging material

4) Avoids loose product core pipes by tightening first and loosening after exchanging

core and winding

5) Automatically indicates "to add the core pipe" and stops machine when there are

no core pipes

6) Automatically stops the machine when paper breaks off

7) Each jumbo roll unwinding is separately equipped with tension control

8) Convenient core pipe winding exchanging adjustment

9) Paper is left in products for sealing

10) Stand is installed on jumbo roll and pushed by a pneumatic device

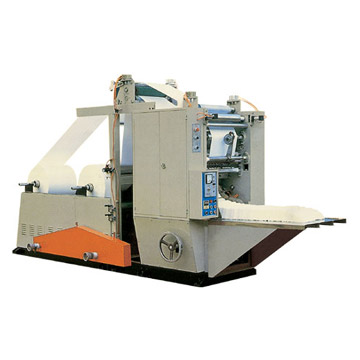

11) Two sets of embossing rollers are adopted to produce dot-by-dot products

12) Two embossing stands can be equipped with three laid paper stands

13) Can be equipped with three embossing rollers and three laid paper stands

14) Can produce paper of 2.2m or 2.6m width

15) Can be equipped with 1 - 2 color printing equipment

16) Embossment pattern can be selected by users

17) Machine power: 8.5kW (380V 50Hz)

18) Production speed: 120 - 160m/min

19) Overall size (excluding embossing stands and laid paper stands):

5.3 x 2.7 x 1.8mm

20) Equipment weight (including embossing stands, laid paper stands and cutting

machine set): about 4MT

21) Finished product diameter: φ80 - φ150mm

22) Punching line distance: 100 - 200mm

23) Jumbo roll width:

a) SP92B type: 1.2m

b) SP75B type: 1.8m

1) High automation, complete function and high efficiency programmable control

system

2) Automatically exchanges core, then winds, sprays glue and seals without stopping

3) Automatically raises and lowers speed when exchanging material

4) Avoids loose product core pipes by tightening first and loosening after exchanging

core and winding

5) Automatically indicates "to add the core pipe" and stops machine when there are

no core pipes

6) Automatically stops the machine when paper breaks off

7) Each jumbo roll unwinding is separately equipped with tension control

8) Convenient core pipe winding exchanging adjustment

9) Paper is left in products for sealing

10) Stand is installed on jumbo roll and pushed by a pneumatic device

11) Two sets of embossing rollers are adopted to produce dot-by-dot products

12) Two embossing stands can be equipped with three laid paper stands

13) Can be equipped with three embossing rollers and three laid paper stands

14) Can produce paper of 2.2m or 2.6m width

15) Can be equipped with 1 - 2 color printing equipment

16) Embossment pattern can be selected by users

17) Machine power: 8.5kW (380V 50Hz)

18) Production speed: 120 - 160m/min

19) Overall size (excluding embossing stands and laid paper stands):

5.3 x 2.7 x 1.8mm

20) Equipment weight (including embossing stands, laid paper stands and cutting

machine set): about 4MT

21) Finished product diameter: φ80 - φ150mm

22) Punching line distance: 100 - 200mm

23) Jumbo roll width:

a) SP92B type: 1.2m

b) SP75B type: 1.8m

Related Search

High Speed Rewinding Machine

Dot Peen Marking Machine

Paper Rewinding Machine

Dot Matrix

DOT Helmet

Dot Motorcycle

More>>